Egyptian Faience Produced at Caer Alyn

Background

The Faience Kiln at Caer Alyn came about because the archaeometry project at Daresbury had been investigating the production of Egyptian Faience. I had been involved with the investigation, specifically the firing side of the project. After reading the Eccleston paper (Eccleston, M. A. J. 2008. ‘Replicating Faience in the bread oven at Amarna’, Egyptian Archaeology 32, pp33-5) I decided that building a clay bread oven at Caer Alyn and firing some faience would be an interesting experimental archaeology project. Also, this experiment had never been attempted outside Egypt (so it would be a first for Caer Alyn and the UK).

I then met Dr Campbell Price (Curator of Egypt and Sudan, Manchester Museum) when he did a public lecture at Daresbury. I told him about our plan to reconstruct a faience kiln at Caer Alyn and he was very interested. At the time he was redeveloping the Egyptian gallery at the museum. He suggested that it would be good to film the reconstruction of the kiln.

Faience

“In ancient Egypt, objects created with faience were considered magical, filled with the undying shimmer of the sun, and imbued with the power of rebirth. For Egyptians, the sculptures, vessels, jewellery, and ritual objects made of faience glimmered with the brilliance of eternity”

Carolyn Riccardelli. “Egyptian Faience: Technology and Production” in Heilbrunn Timeline of Art History. The Metropolitan Museum of Art 2000-2020.

www.metmuseum.org/toah/hd/egfc/hd_egfc.htm (December 2017)

Faience is a non-clay ceramic consisting of a fine quartz sand base, coated with a soda-rich glaze. The colour is provided by a copper-based ingredient. Faience was first produced in the Near East and Egypt in about the 4th millennium BC. It has been assumed that the firing temperature of this material was relatively low, at between 800°C and 1000°C. Also, it has been postulated that it was possible to produce faience in bread ovens, like the bread ovens found at Tell El-Amarna in Egypt. (Eccleston, M. A. J. 2008. ‘Replicating Faience in the bread oven at Amarna’, Egyptian Archaeology 32, pp33-5). Several experiments have been carried out with varying levels of success. Most could produce a blue faience material, but it lacked the nice glossy finish of Egyptian Faience. It was decided to try and replicate one of these experiments at Caer Alyn and see if it was possible to produce a material with a traditional glossy finish.

The initial experiment was carried out on 25th May 2012 and filmed by Manchester Museum. A second kiln was built and fired in 2013. The project was undertaken in conjunction with Daresbury Laboratory Archaeometry Project and Dr Andy Smith.

Method

Kiln Construction (Kiln 1 and 2).

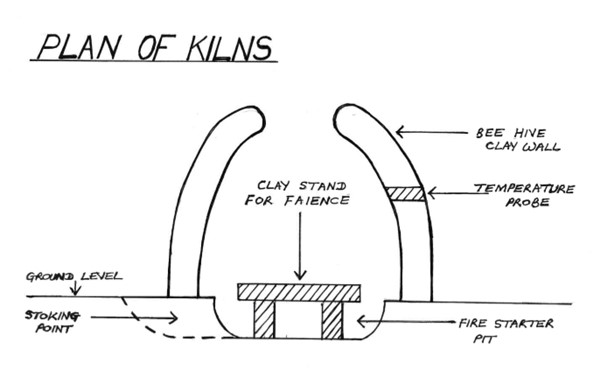

A kiln was constructed based on the Amarna bread ovens. The kiln consisted of a fire pit and a clay beehive-shaped firing chamber. A stoking hole was dug to give access to the fire pit under the dome (see Fig 1 and 2). A recess was made in the side of the beehive to fit the temperature gauge. During the firing the temperature of the kiln was taken at regular intervals.

Fig 1

Fig 2 Construction of the beehive fire chamber.

Faience Recipe

85 parts crushed sand

15 parts ball clay (or gum arabic)

15 parts sodium bicarbonate

15 parts crushed limestone

5 parts copper carbonate

Mixing method

First heat the sand until it can be crushed to a fine powder. Put powdered sand into a large pestle and mortar, add ball clay as a binder (or gum Arabic). Add crushed limestone (crushed to a fine powder) then add copper carbonate and sodium carbonate (natron).

Mix and add water until you get a firm paste. In our case, we added the paste to pre-fired ball clay substrate. This method is known as the ‘application method’ (another method known as the ‘cementation method’ is when the object to be glazed is covered with the powdered glaze material and then placed in the kiln. Both these methods are known to have been used by ancient Egyptian artisans).

The prepared bricks are then placed in the oven. The fire is started and continuously stoked to raise the temperature of the kiln. When the kiln reaches 1000°C, hold the temperature for approximately 2 hours.

Results (25/05/2012).

In our first kiln, the temperature only got to 930°C, so the colour blue was produced but the glazing failed (Fig 3). (For temperature to time ratio, see Fig 4). Interestingly some of the bricks had become red during the firing, this was probably due to reduced oxygen levels in part of the kiln (but further investigation is needed).

Fig 3. Faience in Kiln 1

Fig 4. Kiln 1 – temperature to time ratio.

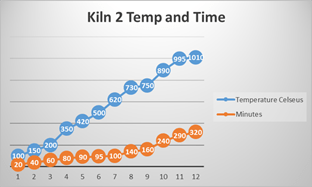

Kiln 2 had a higher firing temperature of 1010°C and the result was much more successful, with a nice glaze produced and a deep blue colour (see Figs 5, 6 & 7).

Fig 5. Kiln 2 being fired.

Fig 6. Faience fired in Kiln 2

Fig 7. Kiln 2 – temperature to time ratio.

Conclusion

Test 1 was fired to a maximum temperature of 930°C and produced a nice pale blue colour (copper migrates to the surface of the faience during the firing process). Unfortunately, there was a minimum surface melt and the Test 1 bricks remained dull and unvitrified.

Test 2 produced a nice glazed surface. It is possible that the introduction of a clay substrate and the higher firing temperature of 1010°C may have been sufficient to vitrify the surface material. In conclusion, it is unlikely that faience was produced at temperatures less than 1000°C but investigations continue.

The film made in 2012 is now a feature of the Ancient Worlds Galleries at the Manchester Museum. Go and see the film and an excellent museum. Thanks, Campbell.

https://egyptmanchester.wordpress.com/tag/faience/

We hope that our experiments can continue when lockdown restrictions are lifted.